फरवरी . 19, 2025 05:15 Back to list

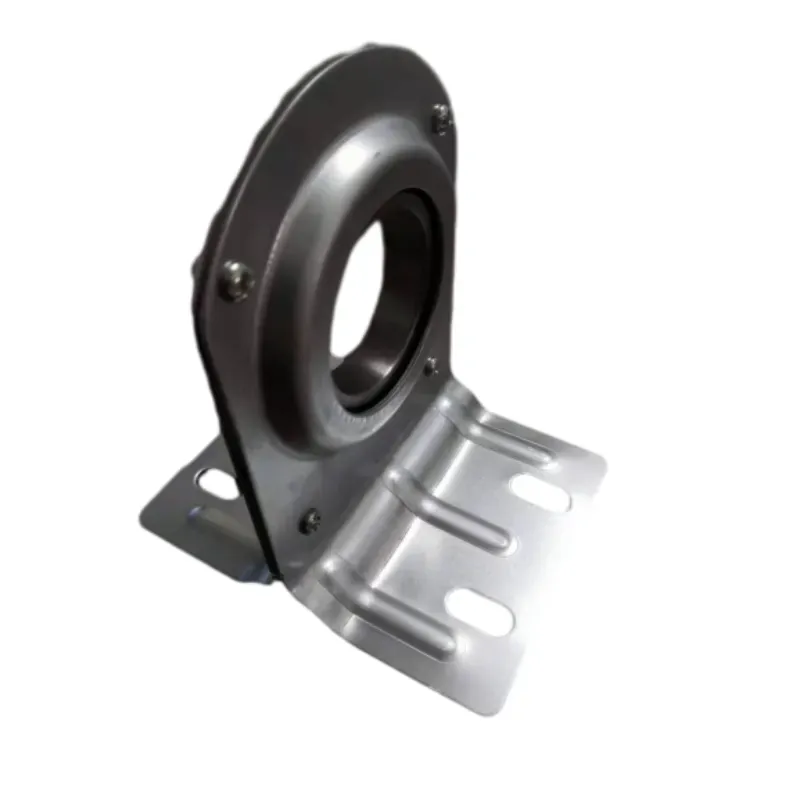

deep groove ball bearing

Deep groove bearings, often dubbed the workhorses of the bearing world, are integral components that serve pivotal roles across various industries. With their unique design and capabilities, they are indispensable in ensuring the efficient operation of machinery, boosting productivity, and minimizing downtime. This comprehensive breakdown delves into the core characteristics, applications, and advantages of deep groove bearings, providing insights drawn from decades of industrial expertise and technical proficiency.

Technological advancements have led to the development of materials and manufacturing processes that enhance the performance of deep groove bearings. Innovations such as high-purity steel, ceramic balls, and precision machining allow for higher load capacities, reduced noise, and increased efficiency. These enhancements cater to the growing demand for bearings capable of performing in extreme conditions or specialized applications. Choosing the right deep groove bearing for a specific application rests on understanding the operational environment and load requirements. Consulting with industry experts or engineers during the selection process can ensure optimal bearing performance and longevity, thus safeguarding investment and enhancing productivity. In the evolving landscape of bearing technology, manufacturers continue to innovate, introducing features like integrated sensors for monitoring bearing health in real-time. These smart bearings offer predictive maintenance capabilities, reducing unexpected downtimes and contributing to a shift towards more intelligent, data-driven maintenance strategies. Given their widespread use and critical function, sourcing deep groove bearings from reputable manufacturers and suppliers accentuates their reliability and performance. Reputable vendors provide the assurance of quality, backed by warranties and robust after-sales support, helping to mitigate risks associated with counterfeit or substandard products. The significance of deep groove bearings in modern industry cannot be overstated. Their robust design, adaptability, and reliable performance are central to various applications, making them indispensable. By prioritizing quality and technological adoption, businesses can leverage these bearings to optimize their operations, reduce costs, and stay ahead in competitive sectors. Harnessing the potential of deep groove bearings begins with knowledge and expertise and is sustained by a commitment to quality and innovation, ensuring these components continue to drive success across industries for years to come.

Technological advancements have led to the development of materials and manufacturing processes that enhance the performance of deep groove bearings. Innovations such as high-purity steel, ceramic balls, and precision machining allow for higher load capacities, reduced noise, and increased efficiency. These enhancements cater to the growing demand for bearings capable of performing in extreme conditions or specialized applications. Choosing the right deep groove bearing for a specific application rests on understanding the operational environment and load requirements. Consulting with industry experts or engineers during the selection process can ensure optimal bearing performance and longevity, thus safeguarding investment and enhancing productivity. In the evolving landscape of bearing technology, manufacturers continue to innovate, introducing features like integrated sensors for monitoring bearing health in real-time. These smart bearings offer predictive maintenance capabilities, reducing unexpected downtimes and contributing to a shift towards more intelligent, data-driven maintenance strategies. Given their widespread use and critical function, sourcing deep groove bearings from reputable manufacturers and suppliers accentuates their reliability and performance. Reputable vendors provide the assurance of quality, backed by warranties and robust after-sales support, helping to mitigate risks associated with counterfeit or substandard products. The significance of deep groove bearings in modern industry cannot be overstated. Their robust design, adaptability, and reliable performance are central to various applications, making them indispensable. By prioritizing quality and technological adoption, businesses can leverage these bearings to optimize their operations, reduce costs, and stay ahead in competitive sectors. Harnessing the potential of deep groove bearings begins with knowledge and expertise and is sustained by a commitment to quality and innovation, ensuring these components continue to drive success across industries for years to come.

Next:

Latest news

-

common-failures-in-thrust-ball-bearings-and-solutions

NewsAug.22,2025

-

how-tapered-roller-bearings-can-take-shock-loads

NewsAug.22,2025

-

angular-bearings-in-high-precision-spindles

NewsAug.22,2025

-

the-impact-of-misalignment-on-cylindrical-roller-bearing-performance

NewsAug.22,2025

-

the-role-of-cage-design-in-deep-groove-ball-bearing-durability

NewsAug.22,2025

-

the-impact-of-material-quality-on-machinery-bearings-lifespan

NewsAug.22,2025