אוק . 16, 2024 15:55 Back to list

Timken Tapered Roller Bearings for Enhanced Load Capacity and Performance

Taper Roller Bearings A Timken Perspective

Taper roller bearings are crucial components in various industries, from automotive to heavy machinery, due to their unique design and functionality. Among the manufacturers leading the market in taper roller bearings is Timken, a company with a rich history dating back over a century. This article delves into the design, advantages, and applications of Timken's taper roller bearings, showcasing their significance in enhancing mechanical performance.

What Are Taper Roller Bearings?

Taper roller bearings are designed to accommodate heavy radial and axial loads. The rolling elements are tapered, allowing for a larger contact area between the roller and the raceway, which helps in distributing loads efficiently. This design enables taper roller bearings to handle both thrust and radial loads, making them ideal for various applications where performance and reliability are paramount.

Timken's Innovations in Taper Roller Bearing Design

Timken has consistently pushed the boundaries of innovation in bearing technology. Their taper roller bearings are engineered to meet the diverse needs of various applications, from automotive wheel hubs to industrial machinery. The unique features of Timken's designs include

1. Precision Engineering Timken employs state-of-the-art manufacturing techniques to produce taper roller bearings with high precision. This not only ensures a perfect fit but also improves the rolling efficiency, which ultimately extends the bearing's service life.

2. Robust Materials The materials used in Timken taper roller bearings are selected for their strength and durability. They often feature heat-treated steel, which enhances wear resistance and helps maintain dimensional stability under heavy loads.

3. Advanced Sealing Solutions To ensure longevity and performance, Timken incorporates advanced sealing solutions in their bearings. These seals protect the internal components from contaminants, moisture, and dust, which can otherwise lead to premature failure.

4. Custom Solutions Recognizing that each application may have unique requirements, Timken offers customized taper roller bearing solutions. This tailored approach allows for greater flexibility and optimization in specific applications, ensuring that clients receive bearings best suited for their needs.

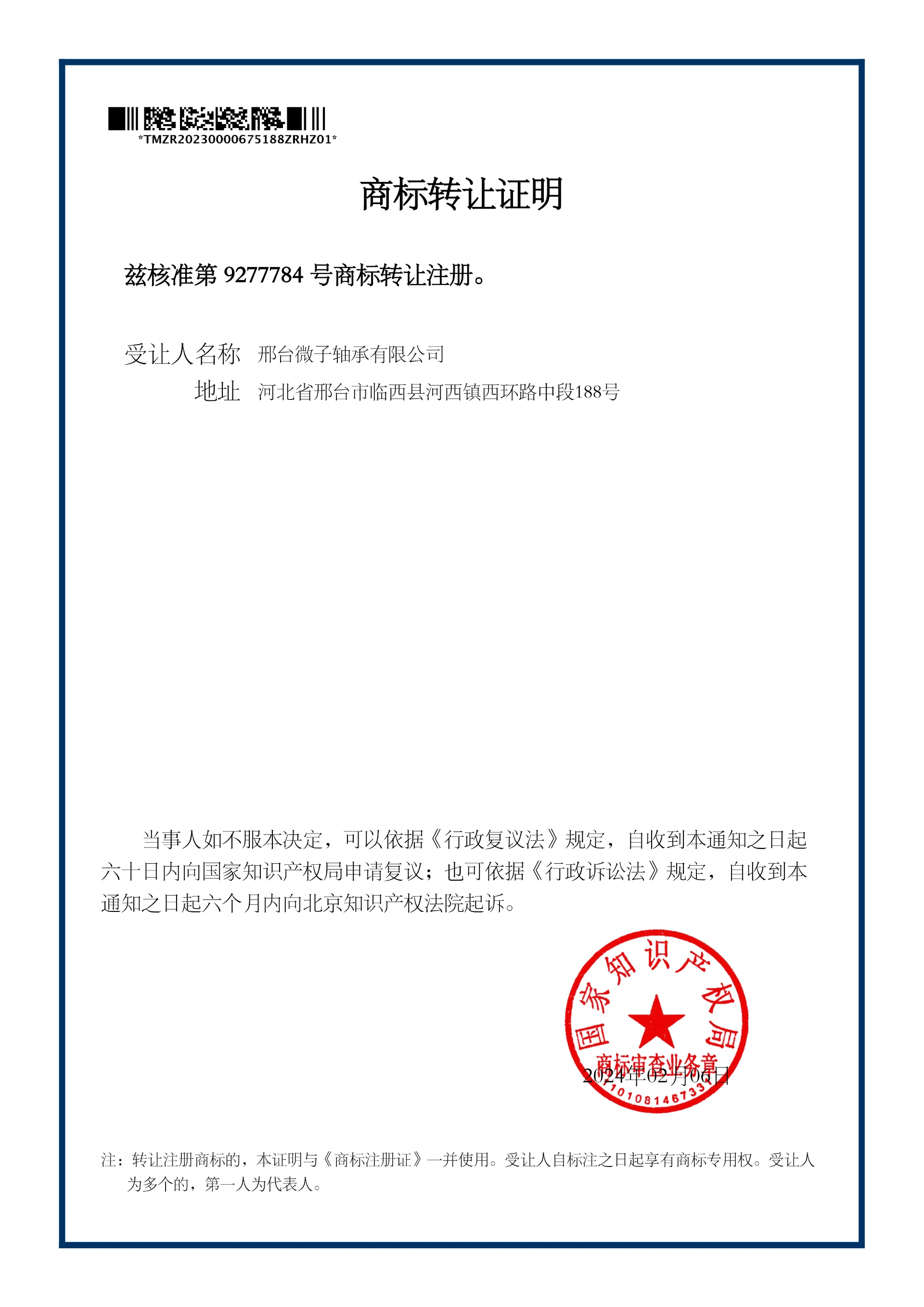

taper roller bearing timken

Advantages of Timken Taper Roller Bearings

1. High Load Capacity Due to their tapered design, these bearings can carry substantial loads, making them suitable for applications involving heavy machinery such as construction equipment and mining vehicles.

2. Versatile Applications Timken's taper roller bearings are utilized in various settings, including automotive, aerospace, marine, and industrial sectors. Their adaptability to different environments and operational conditions is one of their significant advantages.

3. Reduced Friction and Heat Generation With precision engineering, Timken taper roller bearings exhibit lower friction during operation, leading to reduced heat generation. This characteristic is critical in enhancing the overall efficiency of the machinery they support.

4. Enhanced Reliability Timken's commitment to quality and innovation translates into bearings that provide superior reliability. Users can count on their performance over extended periods, reducing the frequency of maintenance and replacements.

Applications in the Real World

Timken taper roller bearings find application in a wide range of industries. In the automotive sector, they are commonly used in wheel hubs, ensuring smooth rotation and stability. In the manufacturing industry, these bearings are essential for conveyor systems and heavy machinery, where they support the load and facilitate movement.

In the aerospace industry, the ability of taper roller bearings to withstand high loads while minimizing weight is invaluable. They provide essential support in aircraft engines and landing gear systems. The versatility of Timken taper roller bearings extends to renewable energy sectors, where they are used in wind turbines to handle the mechanical stresses involved.

Conclusion

Timken's taper roller bearings exemplify the perfect blend of innovation, quality, and performance. Their ability to support heavy loads, adaptability to various applications, and robust design make them a preferred choice across multiple industries. As machinery and applications evolve, Timken continues to lead the way in developing advanced bearing solutions that meet the demands of modern engineering challenges. By investing in Timken taper roller bearings, companies can enhance their operational efficiency and ensure long-term reliability in their mechanical systems.

Latest news

-

common-failures-in-thrust-ball-bearings-and-solutions

NewsAug.22,2025

-

how-tapered-roller-bearings-can-take-shock-loads

NewsAug.22,2025

-

angular-bearings-in-high-precision-spindles

NewsAug.22,2025

-

the-impact-of-misalignment-on-cylindrical-roller-bearing-performance

NewsAug.22,2025

-

the-role-of-cage-design-in-deep-groove-ball-bearing-durability

NewsAug.22,2025

-

the-impact-of-material-quality-on-machinery-bearings-lifespan

NewsAug.22,2025