Nov . 05, 2024 13:29 Back to list

6012 bearing dimensions

Understanding 6012 Bearing Dimensions A Comprehensive Guide

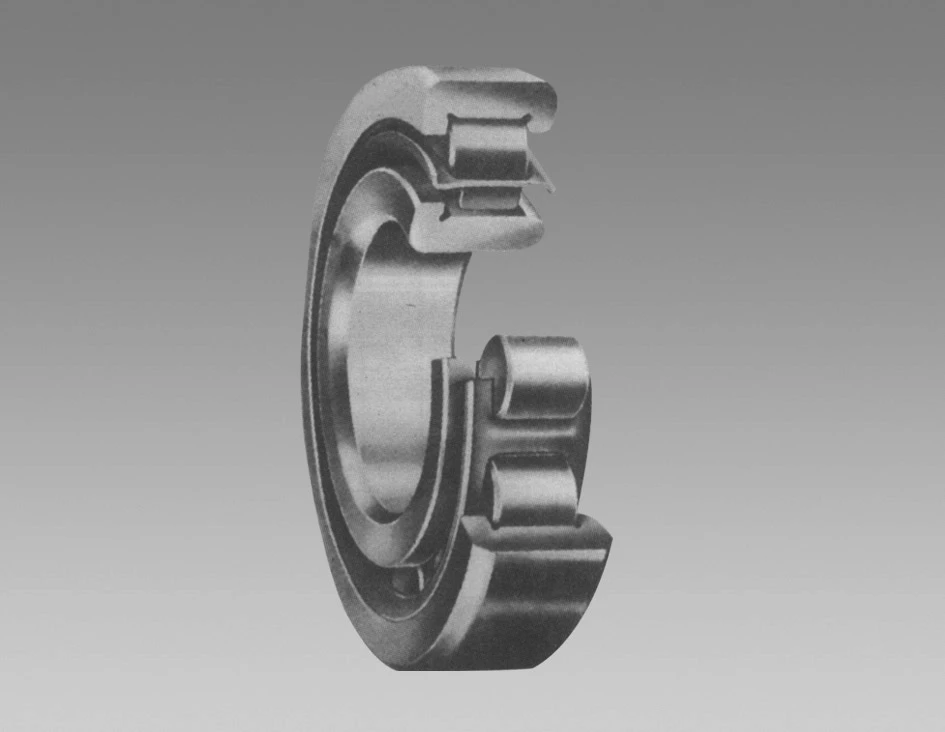

Bearings play a crucial role in numerous mechanical applications, providing essential support and facilitating smooth motion. Among the various types of bearings available, the 6012 bearing is widely used in various industries due to its versatility and reliable performance. This article will explore the dimensions of the 6012 bearing, its applications, and key considerations for selecting the right bearing for your needs.

Understanding 6012 Bearing Dimensions A Comprehensive Guide

One of the defining features of the 6012 bearing is its deep groove design, which allows it to accommodate both radial and axial loads in both directions. This adaptability is a significant advantage in applications where loads may vary or where space constraints limit the use of other bearing types. Additionally, the deep groove configuration contributes to the bearing's ability to operate at high speeds, making it ideal for applications requiring reliable performance under dynamic conditions.

6012 bearing dimensions

When selecting a 6012 bearing, it is essential to consider several factors beyond just size. Operating conditions, such as temperature, speed, and the nature of the application, can significantly impact bearing performance. For instance, if a bearing is subjected to high temperatures or harsh environments, it may be beneficial to opt for a specialized variant, such as those with enhanced sealing or lubrication options.

Moreover, the material composition of the bearing can influence its durability and efficiency. Standard 6012 bearings are typically made from high-carbon chromium steel, providing a good balance of strength and wear resistance. However, for demanding applications, ceramic bearings or hybrid bearings that combine steel and ceramic materials might be preferred for their superior performance and longevity.

In summary, the 6012 bearing, with its standard dimensions of 60 mm inner diameter, 95 mm outer diameter, and 18 mm width, serves as a vital component in various mechanical applications. Its deep groove design allows it to handle a range of loads and speeds effectively. When selecting a 6012 bearing, it is crucial to consider operating conditions and material choices to ensure optimal performance and reliability. Understanding these aspects will help you make informed decisions when integrating this bearing type into your machinery or equipment.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025