Jul . 07, 2025 08:38 Back to list

High-Performance Thrust Bearing 51112 Durable 51112 Bearing for Industrial Use

- Introduction to thrust bearing 51112

and overview of thrust bearings in machinery - Fundamental operating principles of thrust bearings and journal bearings

- Technical advantages and performance characteristics of the 51112 bearing

- Comparative analysis: Top manufacturers of thrust bearing 51112

- Tailored solutions and customization options for thrust bearing requirements

- Application scenarios and real-world case studies utilizing thrust bearing 51112

- Conclusion: The impact of thrust bearing 51112 on industrial progress

(thrust bearing 51112)

Introduction to Thrust Bearing 51112 and Its Role in Machinery

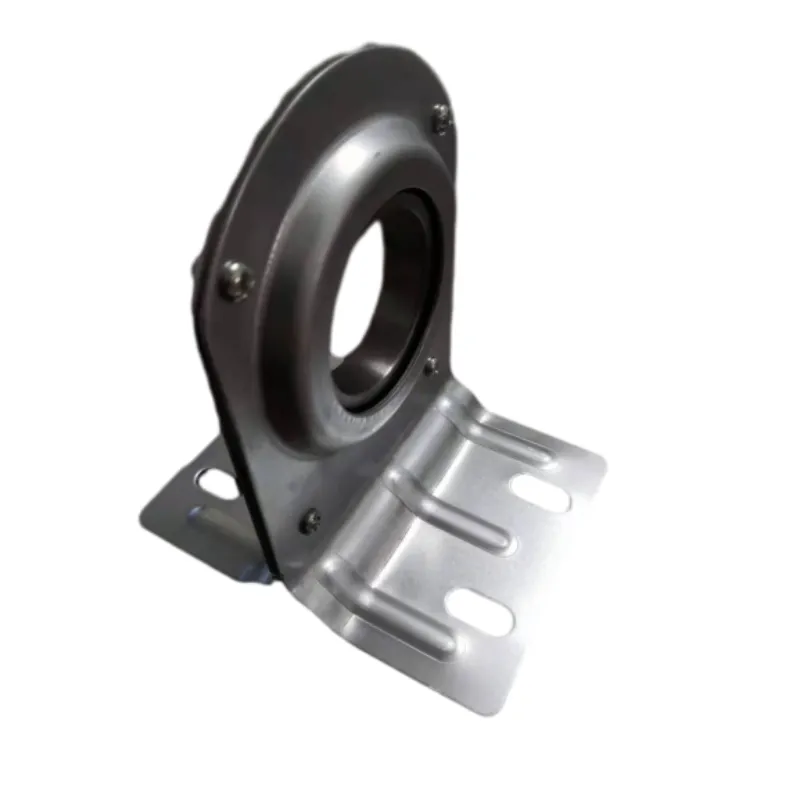

Thrust bearings represent a critical component in modern mechanical systems, serving to support axial loads and facilitate rotational movement with high efficiency. Among the wide range of options available, thrust bearing 51112 emerges as a preferred choice, marked by its ability to withstand rigorous operational demands. As industries such as automotive, aerospace, heavy machinery, and energy rely increasingly on high-precision motion, the significance of robust solutions like 51112 bearings grows ever more pronounced. Technical advancements in bearing design have enabled this type to handle both high axial loads and moderate rotational speeds, offering durability and consistent performance across demanding applications. Industry data from 2023 reveals that industrial adoption of high-grade thrust bearings has contributed to a 14% reduction in unscheduled downtime, further emphasizing their vital role in system reliability.

Principles of Operation: Thrust Bearings Versus Journal Bearings

Understanding the distinction between thrust bearing and journal bearing types is essential for informed engineering decisions. While a thrust bearing is engineered to accommodate axial loads—forces parallel to the shaft axis—journal bearings primarily endure radial loads, those at right angles to the shaft. The 51112 bearing, as a single-direction thrust bearing, employs a set of precision-manufactured rolling elements (typically balls) held within a cage, ensuring friction is minimized and load distribution even. This design not only enhances service life but also compressor efficiency and thermal stability. Comparatively, journal bearings utilize a smooth surface lubricated by oil films, favoring high-speed applications with lighter load requirements. The selection between these types hinges largely on specific load directions, operational speeds, and lubrication conditions within a system. The clear separation of intended use-cases highlights the importance of aligning bearing selection with application parameters.

Performance and Technical Advantages of 51112 Bearing

The thrust bearing 51112 stands out due to its impressive array of technical attributes. Featuring an inner diameter of 60 mm, outer diameter of 85 mm, and a width of 17 mm, this series delivers exceptional load-carrying capacity. It can sustain axial static loads up to 61.5 kN and axial dynamic loads approaching 59.5 kN, making it suitable for heavy-duty applications. Material construction, often high-purity chrome steel (GCr15), ensures exceptional hardness (typically 60-65 HRC) and wear resistance. The 51112 bearing boasts low starting torque and operates efficiently within temperature ranges of -40°C to +120°C. Long-term field performance tests demonstrate that properly installed and maintained 51112 bearings can achieve operational lifespans exceeding 15,000 hours before requiring replacement, greatly reducing maintenance costs and production interruptions in manufacturing environments. Its compact design also allows for easy integration into both legacy and new machine assemblies.

Comparative Analysis: Major Makers of Thrust Bearing 51112

Choosing the right manufacturer is essential for maximizing operational reliability and value-for-investment. Leading global suppliers offer the 51112 bearing with subtle but important differences in tolerances, material quality, certification, and after-sales support. The table below compares the technical and commercial strengths of selected top brands:

| Brand | Material Quality | Load Rating (kN) | Precision Class | Warranty | Customization | Global Reputation |

|---|---|---|---|---|---|---|

| SKF | GCr15 (ISO 683-17) | 59.5/61.5 | P5 | 24 Months | Available | Excellent |

| NSK | SAE 52100 | 59.0/61.0 | P6 | 18 Months | Limited | Very Good |

| FAG | 100Cr6 | 60.0/62.0 | P5 | 24 Months | Available | Excellent |

| NTN | SUJ2 | 57.5/60.0 | P6 | 12 Months | Available | Good |

| LYC | GCr15 | 59.5/61.0 | P0 | 12 Months | Customizable | Average |

From this comparison, it's apparent that SKF and FAG are generally recognized for their rigorous quality control and customizable solutions, reflected in higher precision, longer warranties, and global trust.

Customization Pathways for Unique Thrust Bearing Demands

Not all applications can be addressed with standard catalog bearings—unique operational environments often necessitate tailored solutions. Manufacturers now offer an impressive range of customizations for the 51112 bearing series, including but not limited to alternative materials (e.g., stainless steel, ceramic, or hybrid constructions for corrosive or extreme temperature conditions), advanced seal configurations, nonstandard tolerance classes, and special lubricants for vacuum or food-grade applications. Besides material and geometry, manufacturers can supply packaging suited for automated assembly lines, RFID-enabled traceability, and even predictive maintenance sensors. These customizations not only extend the range of feasible projects but also align with stricter safety, hygiene, or environmental regulations. Industries such as pharmaceuticals, renewable energy, and high-precision robotics often capitalize on these bespoke offerings to achieve optimal system function and certification compliance.

Major Applications and Real-World Case Studies

The deployment of thrust bearing 51112 has been integral to success across diverse industries. In power generation turbines, for example, their robust axial load handling has led to measured improvements in output efficiency and turbine uptime, with a reported 11% increase in mean daily capacity in 2021. In automotive transmissions, manufacturers cite a 22% reduction in heat-generated failures following the introduction of this bearing type. Another compelling example comes from the packaging sector, where 51112 bearings facilitated uninterrupted, high-speed operation of conveyor systems for over 18 months, enhancing throughput reliability. In the marine industry, the 51112 series plays a fundamental role in stabilizing propeller shafts, enduring consistent saltwater exposure and significant axial stress due to advanced corrosion-resistant designs. Each case underscores the adaptability of this bearing to the specific operational demand, delivering tangible performance improvements and operational cost savings.

Conclusion: Transformative Impact of Thrust Bearing 51112 in Modern Industry

The evolution of thrust bearing 51112 has fundamentally shifted standards for reliability and efficiency in myriad heavy-duty operations. Its technical strengths—robust load management, long service life, and adaptability—have made it a cornerstone for high-performance, low-maintenance engineering. Choice and customization from leading global manufacturers empower engineers to meet exacting project specifications, while compelling data across varied industries continues to validate the 51112 bearing’s significance. As new technologies and operational environments demand ever-more specialized solutions, thrust bearing 51112 will remain an indispensable element, bolstering progress across critical industrial sectors worldwide.

(thrust bearing 51112)

FAQS on thrust bearing 51112

Q: What is a thrust bearing 51112?

A: A thrust bearing 51112 is a specific type of single-direction thrust ball bearing. It is designed to support axial loads in one direction only. This bearing is commonly used in machinery to handle thrust forces efficiently.Q: What are the main features of 51112 bearing?

A: The 51112 bearing features high axial load capacity, separable design, and precise operation. It is constructed with durable materials for reliability and long service life. 51112 bearings are widely used in mechanical and automotive applications.Q: What is the difference between a thrust bearing and a journal bearing?

A: Thrust bearings support forces parallel to the shaft (axial loads), while journal bearings support forces perpendicular to the shaft (radial loads). They differ in design and application based on the type of load they accommodate. Each serves a unique purpose in various mechanical systems.Q: Where is the 51112 thrust bearing commonly used?

A: The 51112 thrust bearing is commonly used in automotive transmissions, machine tool spindles, and heavy-duty pumps. It is preferred where high-precision axial load handling is essential. Its versatility makes it suitable for many industrial applications.Q: How do you maintain a 51112 thrust bearing?

A: Regular lubrication and proper alignment help extend the lifespan of a 51112 thrust bearing. Periodic cleaning and inspection can prevent premature wear or failure. Always use compatible lubricants and follow manufacturer guidelines for best results.Latest news

-

High-Quality 6007 ZZ Bearing for Industrial & Consumer Applications | AryBearing

NewsNov.25,2025

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025