Dùbh . 04, 2024 21:29 Back to list

spherical roller bearing failure analysis

Spherical Roller Bearing Failure Analysis

Spherical roller bearings are widely used in various applications due to their ability to accommodate heavy radial loads and moderate axial loads in both directions. These bearings are characterized by their unique design, which includes a spherical outer race and barrel-shaped rollers. Despite their robust design, spherical roller bearings can still experience failures, leading to operational inefficiencies and costly downtime. Understanding the common causes of failure and implementing effective analysis techniques is crucial for maintaining reliability in machinery.

Common Causes of Failure

1. Fatigue Damage One of the most common failure modes in spherical roller bearings is fatigue damage. This occurs due to the repetitive loading and unloading of the bearing, which can lead to the formation of cracks or flaking on the raceways and rollers. The fatigue life of the bearing can be affected by factors such as the material properties, surface conditions, lubrication quality, and load cycles.

2. Wear and Abrasion Over time, contaminants such as dirt, dust, or metallic particles can enter the bearing and cause wear. This abrasive wear can result in material removal from the raceways and roller surfaces, leading to increased clearances and reduced load-carrying capacity. Regular maintenance and proper sealing are essential to prevent wear-related failures.

3. Misalignment Improper installation or changes in the setup can lead to misalignment of the bearing. Misalignment can induce additional stresses on the bearing components, resulting in accelerated wear, overheating, and ultimately leading to premature failure. It is critical to ensure that the shaft and housing align correctly during installation and maintenance.

4. Lubrication Issues Spherical roller bearings depend on adequate lubrication to minimize friction and wear. Insufficient lubrication, contamination of the lubricant, or the use of the wrong lubricant can significantly shorten the bearing's lifespan. It is important to monitor lubrication intervals and ensure that the correct lubricant type is used for specific operating conditions.

5. Overloading Exceeding the rated load capacity of a spherical roller bearing can lead to deformation and premature failure. Overloading can occur due to operational factors or unforeseen circumstances. Proper load calculations and regular assessments of operating conditions are necessary to avoid exceeding load limits.

Failure Analysis Techniques

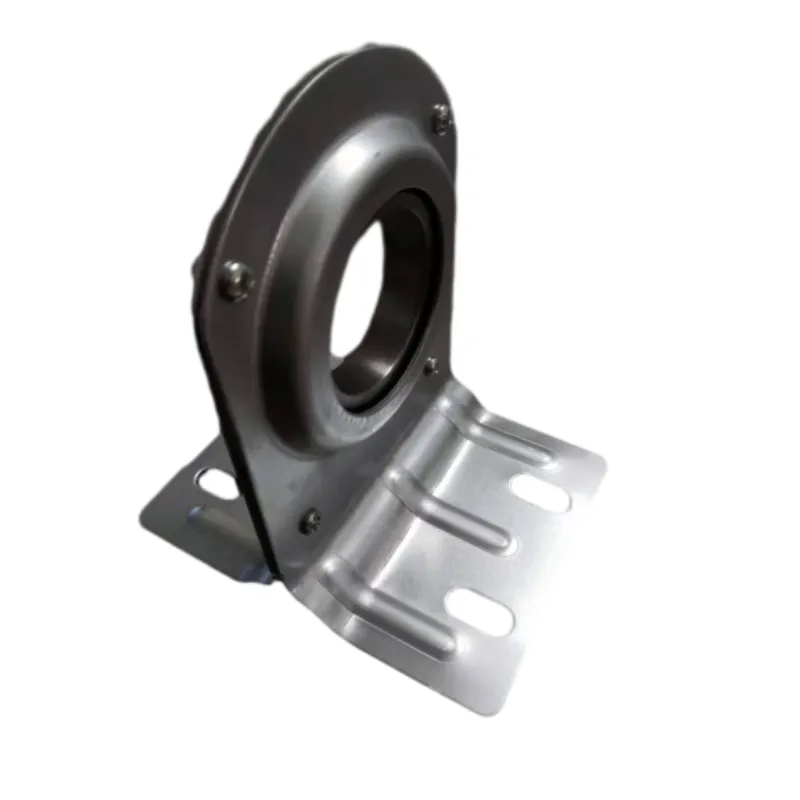

spherical roller bearing failure analysis

When a failure occurs, conducting a thorough failure analysis is crucial to determine the root cause and prevent future occurrences. Several techniques can assist in this process

1. Visual Inspection A preliminary step in failure analysis is to conduct a visual inspection of the bearing and associated components. This can reveal signs of damage, wear patterns, and contamination. Noticing discoloration, pitting, or unusual wear patterns can provide initial insights into the failure mode.

2. Material Analysis If fatigue or cracking is suspected, material analysis techniques such as scanning electron microscopy (SEM) may be employed to investigate the microscopic characteristics of the failure. This can help identify the type of material and any defects that may have contributed to the failure.

3. Non-Destructive Testing (NDT) Methods such as ultrasound and magnetic particle inspection can detect subsurface defects and measure the integrity of the bearing components without causing damage. NDT can be instrumental in identifying potential failure points in bearings before they manifest as problems.

4. Vibration Analysis Regular vibration monitoring can help detect abnormal patterns that might indicate bearing issues. Changes in vibration signatures can signal misalignment, imbalance, or wear. Analyzing vibration data can provide valuable information about the condition of the bearing, allowing for timely maintenance.

5. Lubrication Analysis Examining the lubricant for contaminants, viscosity changes, or degradation can offer insights into lubrication-related failures. Lubrication analysis helps in identifying issues that can lead to failure due to inadequate lubrication or lubricant quality.

Conclusion

Understanding spherical roller bearing failure is essential for maintaining system reliability and performance. By identifying and analyzing the common causes of failure, as well as employing effective analysis techniques, operators can implement corrective actions that enhance the service life of their bearings. Regular maintenance, coupled with a proactive approach to monitoring and analysis, will ultimately lead to improved machinery performance and reduced operational costs.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025