Ots . 19, 2025 02:13 Back to list

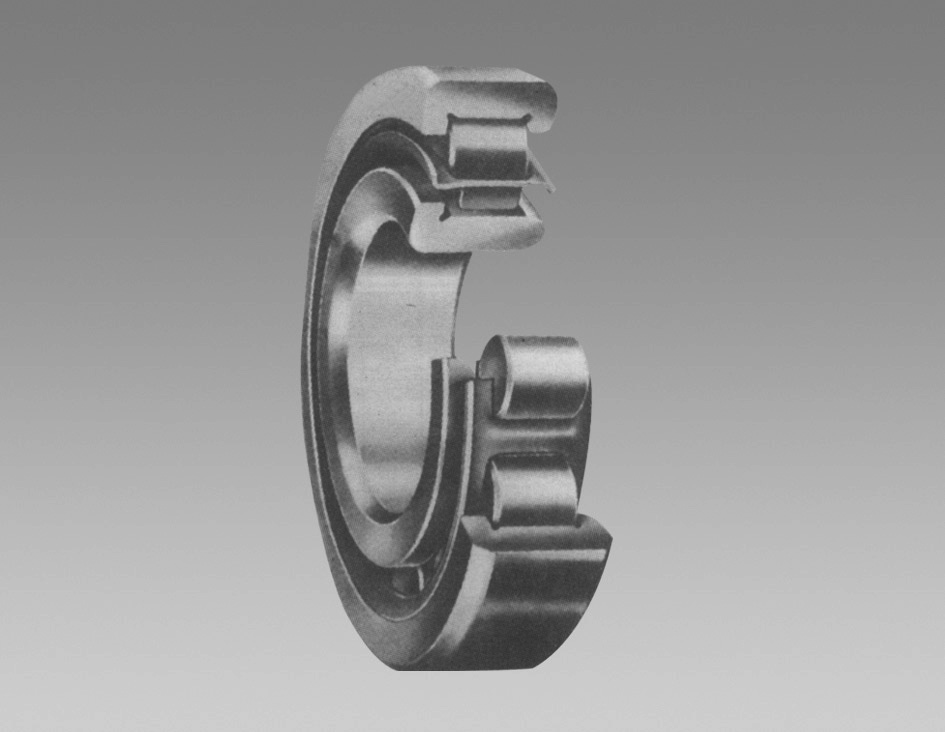

deep groove radial ball bearing

Deep groove radial ball bearings are indispensable components in countless mechanical systems and applications, functioning as the backbone of rotational movements with precision and reliability. Tailored for a spectrum of industries, these bearings boast attributes and capabilities that cater to diverse operational needs, optimizing performance, durability, and efficiency.

From an engineering perspective, proper installation and maintenance of these bearings cannot be overstated. Incorrect installation can lead to premature failure, often evidenced by increased vibrations, irregular noise, or catastrophic breakdowns. Therefore, ensuring that bearings are installed according to manufacturer specifications, with appropriate tools and techniques, is essential for optimal performance. Regular inspections and maintenance regimens can further prevent unscheduled downtime, preserving machine integrity and efficiency. Manufacturers and industry experts perpetually strive to enhance the design and functionality of deep groove radial ball bearings. Advanced simulation and testing methodologies aid in the exploration of new materials and designs, seeking to push the boundaries of operating conditions and extend service life even further. Value-added innovations, such as seals that improve contamination resistance or designs that minimize installation errors, are continually being developed to meet specific industry demands. Trust in deep groove radial ball bearings is also about choosing the right supplier. Leading manufacturers and distributors offer extensive cataloguer explanations, detailed specifications, and customer support to ensure that clients procure the exact product for their specific needs. Moreover, bearing certifications, such as ISO compliance, signify rigorous quality standards, imparting further confidence in product dependability and resilience. Establishing deep groove radial ball bearings as the component of choice for many industries is not just about meeting operational requirements; it’s about exceeding them. As industries evolve and new challenges arise, these bearings adapt through innovation and meticulous design, maintaining their position as a cornerstone of industrial mechanics and a testament to engineering excellence.

From an engineering perspective, proper installation and maintenance of these bearings cannot be overstated. Incorrect installation can lead to premature failure, often evidenced by increased vibrations, irregular noise, or catastrophic breakdowns. Therefore, ensuring that bearings are installed according to manufacturer specifications, with appropriate tools and techniques, is essential for optimal performance. Regular inspections and maintenance regimens can further prevent unscheduled downtime, preserving machine integrity and efficiency. Manufacturers and industry experts perpetually strive to enhance the design and functionality of deep groove radial ball bearings. Advanced simulation and testing methodologies aid in the exploration of new materials and designs, seeking to push the boundaries of operating conditions and extend service life even further. Value-added innovations, such as seals that improve contamination resistance or designs that minimize installation errors, are continually being developed to meet specific industry demands. Trust in deep groove radial ball bearings is also about choosing the right supplier. Leading manufacturers and distributors offer extensive cataloguer explanations, detailed specifications, and customer support to ensure that clients procure the exact product for their specific needs. Moreover, bearing certifications, such as ISO compliance, signify rigorous quality standards, imparting further confidence in product dependability and resilience. Establishing deep groove radial ball bearings as the component of choice for many industries is not just about meeting operational requirements; it’s about exceeding them. As industries evolve and new challenges arise, these bearings adapt through innovation and meticulous design, maintaining their position as a cornerstone of industrial mechanics and a testament to engineering excellence.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025