Okt . 07, 2024 03:40 Back to list

duplex angular contact ball bearings

Understanding Duplex Angular Contact Ball Bearings

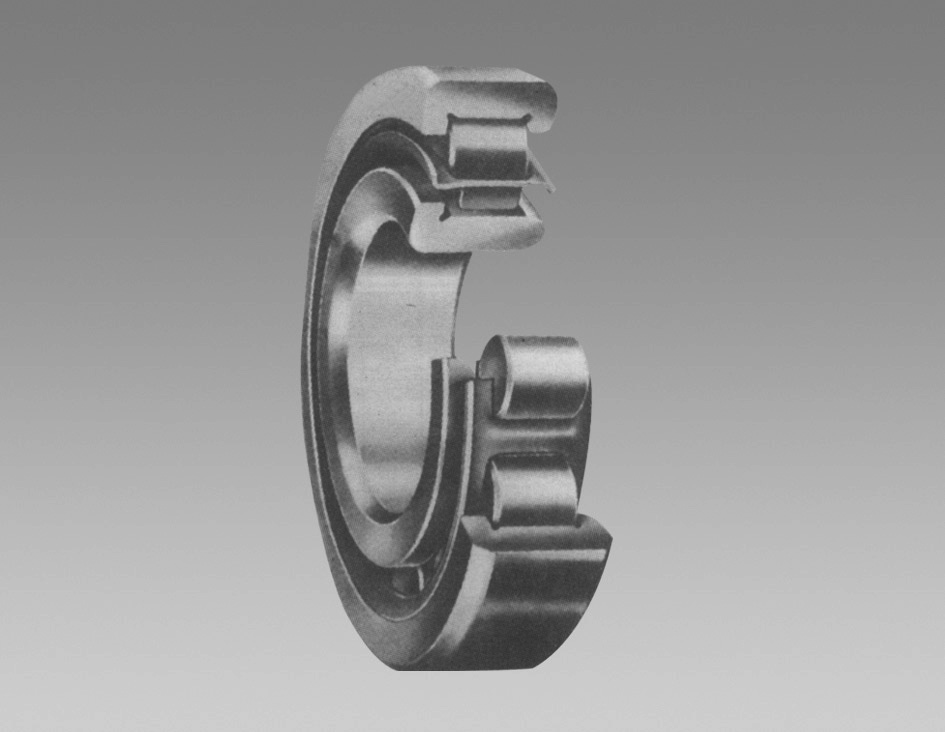

Duplex angular contact ball bearings are specialized types of rolling-element bearings designed to accommodate combination loads, including both axial and radial forces. These bearings are particularly notable for their ability to handle loads in both directions, making them suitable for a variety of applications in industrial machinery and equipment.

The construction of duplex angular contact ball bearings involves the arrangement of two or more angular contact ball bearings in a specific manner to enhance their performance. The term duplex refers to the pairing of two bearings that are mounted face-to-face (DF), back-to-back (DB), or in a tandem arrangement (DT). Each configuration has its distinct advantages depending on the load conditions and alignment of the application.

One of the key benefits of duplex angular contact ball bearings is their ability to achieve higher rigidity. This feature is particularly advantageous in applications that involve high-speed rotation. The angular contact design allows for a greater contact angle, which results in improved load distribution and increased stiffness. Consequently, these bearings can maintain precise alignment and operational stability, essential for the performance of precision machines.

duplex angular contact ball bearings

Duplex bearings are also designed to minimize friction and wear. The carefully engineered geometry of the bearing raceways and the balls facilitates smooth rotation, which is vital for applications requiring low friction and high efficiency. This not only extends the service life of the bearings but also contributes to lower operating costs by reducing energy consumption.

Applications for duplex angular contact ball bearings span across various industries, including aerospace, automotive, and manufacturing. They are commonly found in machine tools, electric motors, and high-speed spindles, where performance and reliability are crucial. In these contexts, the ability to withstand dynamic loads and maintain precise positioning is paramount.

Maintenance and proper installation of duplex angular contact ball bearings are essential to ensure optimal performance. Users must be aware of the load ratings, lubrication requirements, and alignment tolerances to achieve the best results. Additionally, understanding the specific benefits of the DF, DB, and DT configurations can greatly influence the selection process for a given application.

In conclusion, duplex angular contact ball bearings are indispensable components in modern machinery, designed to handle complex loading scenarios with enhanced rigidity and efficiency. Their unique configurations and operational benefits make them ideal solutions for high-performance applications, ensuring reliability, precision, and longevity in various industrial settings.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025