des. . 15, 2024 10:30 Back to list

Exploring the Features and Applications of 51117 Bearing in Modern Machinery

Understanding the 51117 Bearing Specifications, Applications, and Maintenance

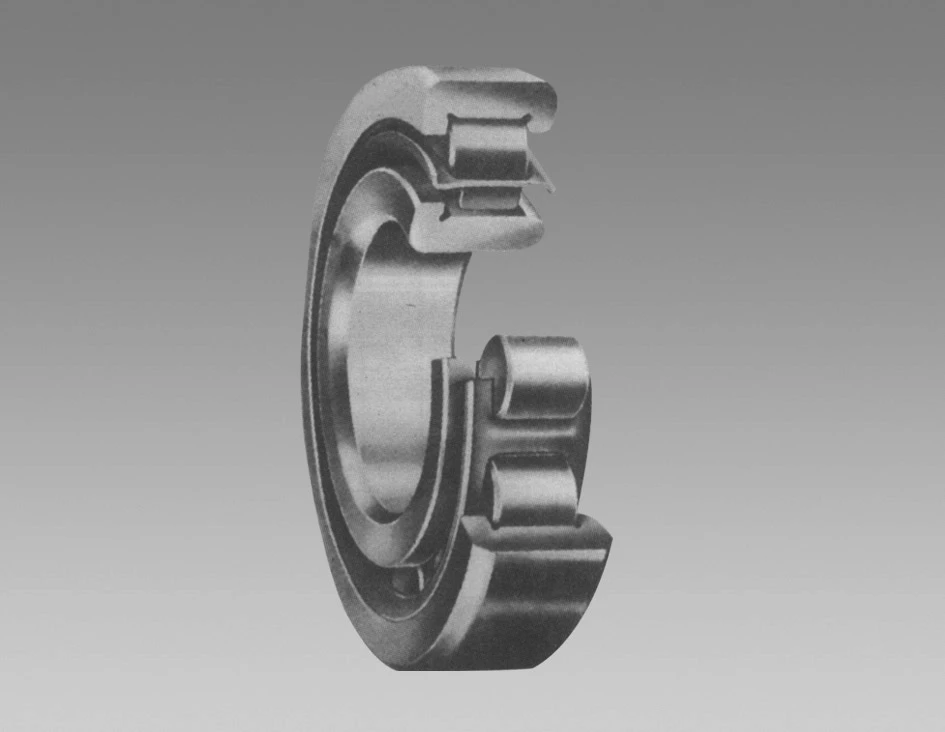

Bearings play a crucial role in the functioning of various mechanical systems, providing the necessary support and reducing friction between moving components. Among the multitude of bearing types, the 51117 bearing stands out due to its specific design and applications. This article will delve into the specifications, applications, and maintenance of the 51117 bearing, offering a comprehensive understanding of this essential component.

Specifications of the 51117 Bearing

The 51117 bearing is classified as a thrust ball bearing, designed to accommodate axial loads in one direction. Its unique construction allows it to support high axial loads while minimizing friction. The key specifications of the 51117 bearing include

- Inner Diameter (d) 85 mm - Outer Diameter (D) 110 mm - Width (B) 25 mm - Dynamic Load Rating (C) Varies based on manufacturer, but typically around 63 kN - Static Load Rating (C0) Approximately 80 kN - Speed Limit The maximum speed rating varies depending on the application and lubrication but is generally around 1,500 to 2,000 RPM.

These specifications highlight the bearing's ability to handle significant loads while maintaining performance in demanding environments.

Applications of the 51117 Bearing

The 51117 bearing is utilized in various industrial applications owing to its capacity to support axial loads. Common applications include

2. Agricultural Equipment Tractors and other farming machinery often rely on the 51117 bearing for its robustness and reliability under heavy loads, ensuring smooth operation during critical tasks.

3. Electric Motors In applications where motor shafts experience significant axial loads, the 51117 bearing effectively supports the shaft while minimizing friction and heat generation.

51117 bearing

4. Industrial Gearboxes The bearing’s design is particularly suited for gearbox applications, where it can handle the axial forces generated by gears and allow for smooth rotation.

5. Pumps and Compressors In fluid transfer operations, the 51117 bearing can help maintain alignment and support the axial loads found in pumps and compressors, contributing to the overall efficiency of the system.

Maintenance of the 51117 Bearing

Proper maintenance of the 51117 bearing is essential to ensure its longevity and performance. Here are some key maintenance practices

1. Regular Inspection Frequent checks should be conducted to identify any signs of wear or damage. Look for unusual noises, excessive play, or visible signs of deterioration.

2. Lubrication Adequate lubrication is critical for minimizing friction and ensuring smooth operation. Depending on the application, grease or oil should be used, and the frequency of lubrication should be based on the operational conditions.

3. Temperature Monitoring Keeping an eye on the operating temperature can help prevent overheating. Elevated temperatures may indicate inadequate lubrication or misalignment, which should be addressed promptly.

4. Alignment Checks Proper alignment of the shaft and bearing is crucial to minimize wear on the bearing surfaces and prevent premature failure. Regular alignment checks can help maintain optimal performance.

5. Load Management Avoiding exceedance of the bearing's load capacity is vital. Operators should ensure that the bearing is not subjected to loads beyond its rated specifications, as this can lead to early failure.

Conclusion

The 51117 bearing is a vital component in many industrial applications, providing reliable support and efficiency in systems that require the handling of axial loads. Understanding its specifications, applications, and maintenance practices can help ensure optimal performance and longevity. Whether in heavy machinery, agricultural equipment, or electric motors, proper care and use of the 51117 bearing can significantly enhance operational efficiency and reduce the risk of unexpected failures.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025