Nov . 15, 2024 17:57 Back to list

61800 zz bearing

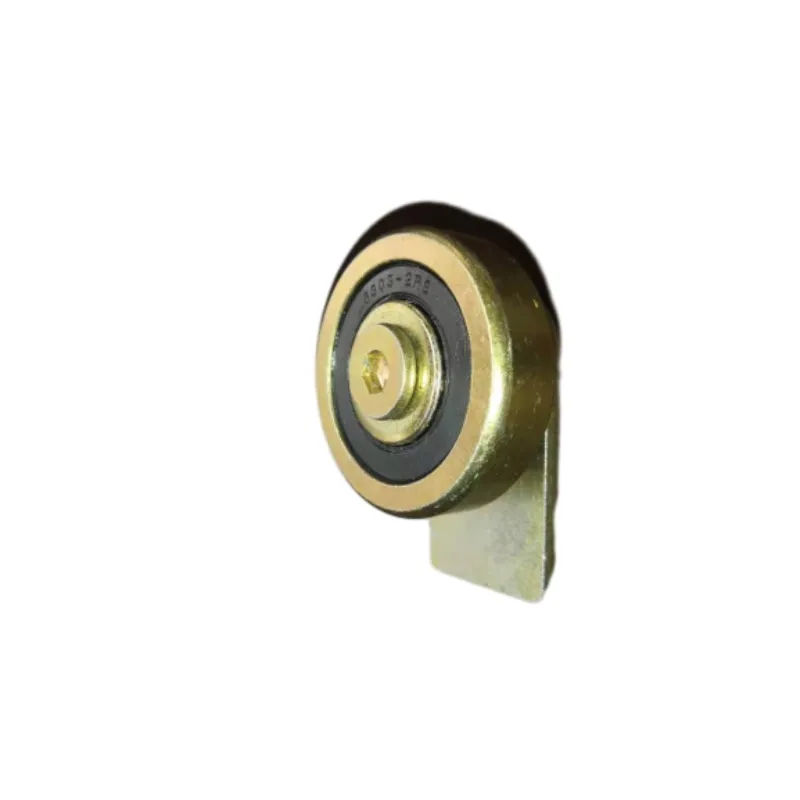

Understanding the 61800 ZZ Bearing A Comprehensive Overview

Bearings are critical components in machinery and devices that facilitate smooth motion and reduce friction between moving parts. Among the various types of bearings, the 61800 ZZ bearing stands out due to its unique features and widespread applications. This article will provide a detailed overview of this specific bearing, its characteristics, applications, and maintenance tips.

What is the 61800 ZZ Bearing?

The 61800 ZZ bearing is a type of deep groove ball bearing, characterized by its deep inner and outer races that allow it to handle high speeds and radial loads effectively. The designation ZZ indicates that it comes with metal shields on both sides, which serve the purpose of protecting the bearing from dust, dirt, and other contaminants while retaining lubrication.

Typically made from high-quality chrome steel, these bearings boast excellent corrosion resistance and durability. The 61800 series is often used for applications requiring high precision and reliability. The dimensions of the 61800 ZZ bearing are standard, with an inner diameter of 10 mm, an outer diameter of 19 mm, and a width of 5 mm. This compact size makes it suitable for various applications where space constraints exist.

Key Features of 61800 ZZ Bearing

1. Low Friction Thanks to its design and high-quality materials, the 61800 ZZ bearing offers minimal friction, reducing wear and prolonging the bearing’s lifespan.

2. High Speed Capability This bearing can operate efficiently at high speeds, making it ideal for dynamic applications where speed is a critical factor.

3. Versatile Applications The compact size and robust design allow the 61800 ZZ bearing to be used in various industries, including automotive, robotics, and home appliances.

4. Protective Shields The ZZ designation signifies the presence of metal shields on both sides, which not only keep contaminants out but also help retain lubricant within the bearing. This is crucial for ensuring longevity and performance.

5. Ease of Installation The design of the 61800 ZZ bearing allows for easy installation, making it accessible even for individuals with limited mechanical experience.

Common Applications

61800 zz bearing

The 61800 ZZ bearing finds its way into numerous applications. Some of the common uses include

- Electric Motors Used in various types of motors for smooth rotation and efficient energy transfer. - Automotive Components Often found in both the under-the-hood applications and in vehicle accessories. - Industrial Machinery Employed in conveyor systems, air compressors, and other machinery where precision and efficiency are vital. - Home Appliances Commonly used in fans, washing machines, and other household devices to achieve quiet and efficient operation.

Maintenance Tips

To ensure the longevity and performance of 61800 ZZ bearings, proper maintenance is essential. Here are some tips

1. Regular Inspection Regularly check for signs of wear, noise, or overheating. Early detection of issues can prevent further damage.

2. Keep It Clean Although the ZZ design offers some level of protection against contaminants, it’s still wise to keep the surrounding environment clean.

3. Avoid Overloading Always adhere to the load specifications outlined by the manufacturer. Exceeding load limits can lead to premature failure.

4. Lubrication While the bearing comes pre-lubricated, it’s important to periodically check lubrication levels and apply additional grease if necessary.

5. Temperature Control Monitor operating temperature, as excessive heat can deteriorate the bearing material and lubricant.

Conclusion

The 61800 ZZ bearing is a remarkable component with excellent performance characteristics and versatility across various applications. Understanding its features, uses, and maintenance requirements can significantly enhance the lifespan and efficiency of the machinery in which it is incorporated. By investing in quality bearings and adhering to best practices for maintenance, users can ensure reliable and efficient operation of their equipment for years to come.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025